As an Amazon affiliate, we earn a commision from qualifying purchases.

Previously, we saw how you can fix your GE washer if it won’t spin or drain. Today, I will be telling you how you can fix your GE washing machine if it is not spinning or agitating.

Without further ado, let’s get started.

GE washing machine not spinning or agitating – causes and possible fixes you can try

Start by…

Checking if water is flowing into the washer

Here’s the thing: If water is not flowing into the washer, then the washer will definitely not start a cycle.

That’s why your washer won’t spin or agitate.

Troubleshooting steps you can try

Start by confirming that both water faucets (hot and cold) are fully open.

Proceed to inspect the water inlet hoses – if they have kinks or twists, be sure to straighten them out.

If in the process you note that the hoses are leaking, you can try to patch them up.

However, if this does not work, my advice is you get a replacement inlet hose.

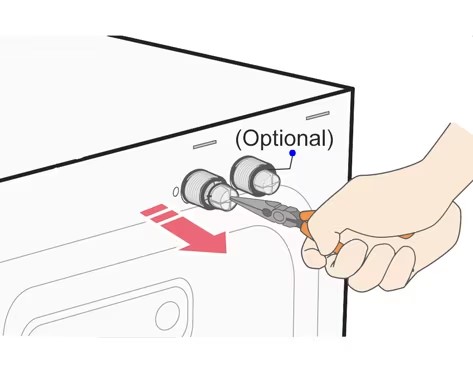

Once you are done, proceed to disconnect the hoses from the washer by turning them anticlockwise as shown:

Using pliers, pull out the mesh filters (using pliers) as shown:

Once you successfully remove the mesh filters, proceed to clean them under running water – you can use a soft toothbrush to scrub any mineral buildup that might be in there.

The final part you should inspect is the water inlet valve… You see, a bad inlet valve will not open to let water flow into the unit. As a consequence, the washer won’t start an agitate or spin cycle.

Here, start by disconnecting and reconnecting the valve’s wire harness connector – at times the connector might be loose hence why the valve is not working.

While still in there, confirm that the valve is getting enough power (110-120v AC). To confirm this, insert the multimeter probes into the valve’s wire connector while the washer is running.

If the valve is not getting enough power and the wires are good, it means the control board is defective.

Here, your best choice will be to swap out the board – shop for replacement board on Amazon.

On the other hand, if your voltage checks out, proceed to test the valve for continuity by touching the multimeter probes to the valve terminals.

If the valve lacks continuity, it means that the valve is bad. Here, your best course of action will be to get a replacement inlet valve.

The load size might be too small or too large

Did you know that washers will not spin or agitate if the load size is too small?

That’s right. You see, the sensors in the washer might be unable to sense small loads resulting in your washer not running.

This will normally be the case if you have thrown one or two light clothes.

So, if you are trying to wash a small load, try adding two or three towels to make it easier for the washer to sense your load.

Something else: If you are overfilling the washer beyond the balance ring, it might put undue stress on the suspension rods and the motor making it hard for these parts to spin the drum.

Additionally, the extra load might make it hard for the agitator to agitate during a wash cycle since the load might be too packed inside the drum.

So, how can you make sure that you’re not overloading your appliance?

As a general rule of thumb, always make sure you are not loading the washer more than ¾.

The washer might not be properly balanced

For the most part, this applies to top load washers as they are more likely to get unbalanced depending on the load size.

Quick tip: In most GE washers, the Spin light will blink to indicate that the load is not properly balanced. In some models, it will be the Spin and Rinse indicator lights that will be blinking.

In models that have a digital display, they might display an UE error code to indicate an unbalanced load.

With that in mind, my advice is you try re-distributing the load evenly to balance your washer better.

The lid/door might not be locking into place

In washing machines, the lid/door acts as a safety switch that prevents the appliance from running if it detects the door as open.

That is why your GE washer might display either the dE or the E2 error codes to indicate that the door is open.

Having said that, do you hear a slight click when you close your washer’s lid/door?

If no, it means that the door is not latching fully.

When this happens, try to shut the lid a little bit harder (till you hear a ‘click’) – at times, this does the trick.

It could also be that the door hook is not properly aligned to the latch – you can try realigning them.

On the other hand, if the lock is clicking into place, disconnect the appliance from the power outlet and open it to access the lid lock switch assembly.

Now confirm that the lid switch wire harness is fully inserted into the control board because many times, this is usually the problem.

For best results, I recommend you try disconnecting and reconnecting the harness.

Finally, using a multimeter, test the lid switch for continuity… If it’s good, it should have continuity when you close the door and no continuity when the door is open.

So, if you are getting different results, it means your washer’s lid/door switch is defective and needs to be replaced.

Foreign object(s) might be caught between the tub and the basket

Other times, I have across washers that won’t spin or agitate due to small foreign objects (such as socks) getting caught between the wash tub and the basket.

The good thing is that you can easily tell if this is the problem with your washer by manually rotating the drum/agitator… Does it feel tight or firm?

If yes, it could be that there is a foreign object trapped in there that you should inspect it.

Of course, this means you will need to take the tub and basket apart.

The drive/transmission pulley might be defective

This pulley is mounted on the drive motor and it doubles as a gear for the mode shifter to lock into place during agitation.

If this pulley is bent/broken, it might also result in your GE washer not spinning or agitating.

So, be sure to also inspect the part… If it is bent, you can try straightening it out.

Fortunately, if it is bent beyond repair (or it’s fully damaged) you can still purchase a replacement transmission pulley to replace the old one.

The speed/hall sensor might be faulty

In most GE washers, this sensor is mounted to the drive motor and it sends a signal to the control board on the movement of the motor.

If the sensor does not send a signal, it will result in the washer agitation and spin cycles not running.

How you can troubleshoot/test the hall sensor

There are two ways that you can use to test if the speed sensor is good or bad. And they are:

1. Running the spin test in service mode

If the sensor is bad/disconnected, the wash basket will start spinning normally, at first.

However, after around 5 seconds, power to the motor will be cut and a locked rotor fault will be displayed.

On the other hand, if the washer continues to spin for at least 15 seconds, it means that the speed sensor is good.

2. Testing the voltage

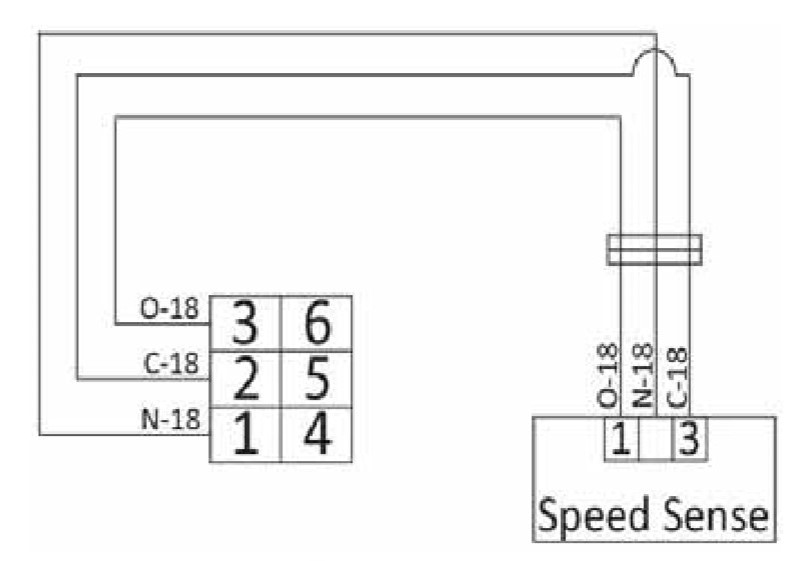

On your control board, locate the J602 connector and test the voltage on pins 3 through 5… If the hall sensor is good, you should get a reading of approximately 9v DC.

Next, measure the voltage through pins 1 and 5 – you should get a reading of around 4.5v DC when rotating the basket.

So, if you are getting a different reading, it means that your washer’s hall sensor is bad hence the need to replace it.

The mode shifter (shift actuator) might be defective

The mode shifter consists of a motor that operates by receiving 120v AC from the control board, a micro switch, and a spring and clutch.

It works by engaging and disengaging the clutch with the transmission pulley depending on whether the current cycle is in spin or agitate.

How to test if the mode shifter is defective

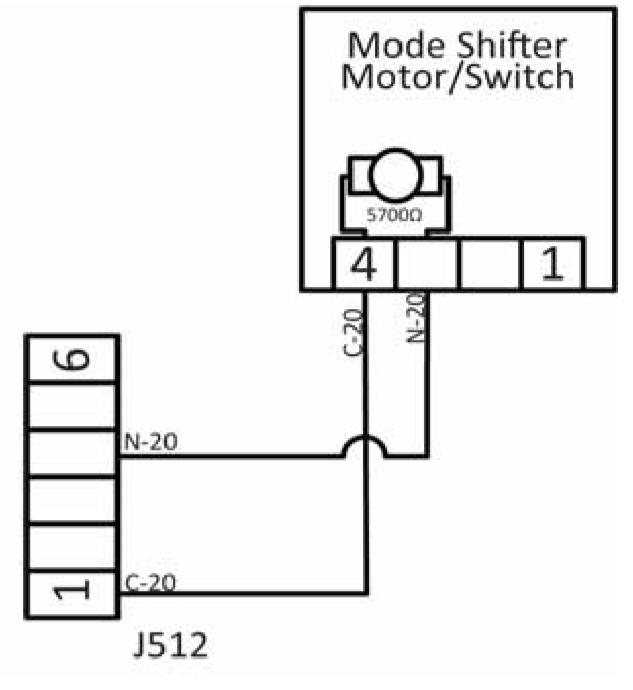

Start by locating the J512 connector on the control board.

Using a multimeter (set to resistance), insert the probes into pin 1 (brown wire) and pin 4 (blue wire).

If the mode shifter is good, you should get a reading of approximately 5,700 Ω. If you are getting a different reading, this is a good sign that you’re looking at a bad mode shifter.

Fortunately, the mode shifter is a replaceable part – shop for a replacement shifter on Amazon.

Additionally, you can confirm that it is getting around 120v AC (through the 2 black motor wires on the mode shifter) when it’s running.

How to diagnose if the mode shifter switch is faulty

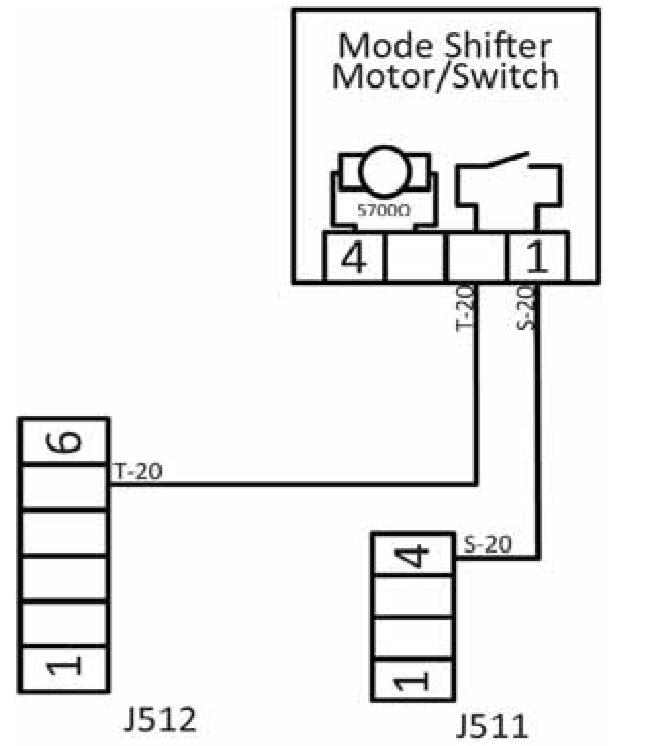

Start by locating the J512 and the J511 connectors on the control board.

Using a multimeter, test for continuity through J512 pin 5 (tan wire) to J511 pin 4 (gray wire).

The switch should be closed during agitation and open during the spin cycle.

Quick tip: The mode shifter switch’s default position is open.

If you are getting a different reading, it means that your switch is defective and you should replace it.

Unfortunately, since you cannot purchase a switch on its own, your best option will be to order a genuine replacement mode shifter on Amazon.

The platform/transmission assembly might be defective

The platform assembly not only houses the transmission but it is also used to mount the drive motor and the mode shifter.

Additionally, it has planetary gears that assist with the agitation and spin cycles.

I am sure you can now see how it plays an important role in the washer’s spinning and agitation.

Fortunately, you can quickly tell if the transmission assembly is faulty by disassembling the washer and running an agitate/spin cycle… If the transmission input shaft rotates but the agitator does not (or the motor engages but the agitator does not), it’s a sign that the transmission assembly is bad.

Similarly, if the input shaft rotates but the drum does not spin, it’s another sign of a bad transmission assembly.

In the event that your transmission assembly is bad, your best cause of action will be to replace the assembly as a whole.

This is because most replacement part manufacturers do not supply the internal parts individually.

Something else: You should be prepared to replace the tub seal located where the shaft enters the tub as this seal is likely to get damaged during the replacement process.

With that in mind, you may want to check the current prices for an original transmission shaft assembly.

The motor coupling might be worn out or faulty

The motor coupling connects the drive motor to the transmission assembly.

What happens when you overload your washer is that you might exert too much pressure on the coupling which might result in the coupling failing.

Moreover, the motor coupling might fail over time due to normal wear and tear. And, when this occurs, the coupling might lose its grip on the transmission shaft.

As a result, your washer is likely to stop agitating or spinning.

You can tell if the coupling is bad by carefully inspecting it for any signs of cracks or damage.

Fortunately, if it is defective, you can get a replacement coupling at a super cheap price – see current prices on Amazon.

Something else: Remember not to load your washer past ¾ way so as to protect the motor coupling from damage.

You might be looking at a bad drive motor

The drive motor is responsible for almost all the spin and agitate cycles that take place in your GE washer.

That’s why, if it fails, it might result in your GE washing machine not agitating or spinning problem.

Quick tip: GE washers have one of two motor types… Either a 1/3 horsepower or ½ HP motor.

Fortunately, you can quickly tell them apart by looking at them – the 1/3 HP motor has a red label on it plus the belt that goes with it will also have red lettering on it.

How you can diagnose and test the drive motor

Start by checking for and removing any foreign objects that might be preventing the motor from running.

Something else: If the drive belt is loose, tighten it using the drive pulley.

On the other hand, if the belt is worn out or torn, my advice is for you to get an exact replica replacement drive belt (Check pricing).

Moving on…

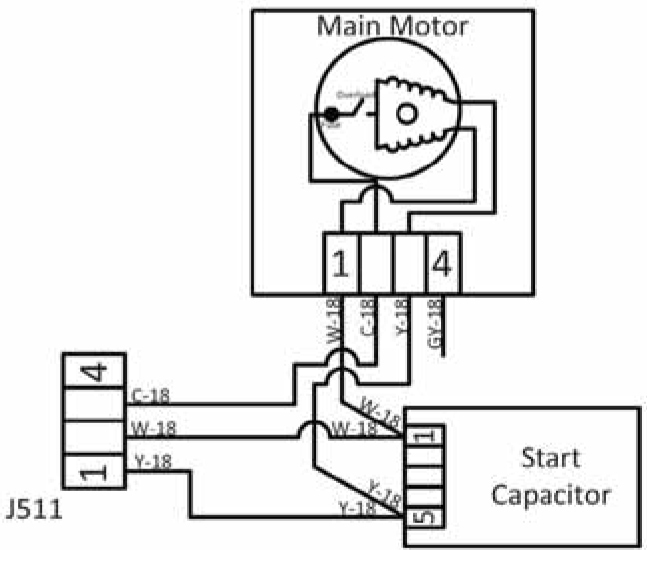

Locate the J511 connector on the control board. Using a multimeter, measure the resistance values between the brown/white and brown/yellow wire pins…

If all is good, you should get a reading of around 3.1 ohms for a ½ HP motor and a reading of approximately 3.8 ohms for a 1/3 HP motor.

If you’re getting a different reading, it’s a good sign of a bad motor- Again you can easily get a new motor on Amazon.

Another test you should perform is a voltage test – a good washer motor will have a reading of 110-120v AC.

However, if yours is getting a different reading start by confirming that your washer is getting 110-120v AC from the power outlet.

If the outlet is good, it’s likely that your washer’s control board is defective and needs replacing.

Quick tip: Before replacing the control board or the motor, first try to disconnect and reconnect the motor wire harness connectors (both at the motor and the control board). This is because at times the problem is usually due to lose wire connections and this might do the trick.

The capacitor might be bad

Word of caution: Before you start testing the capacitor, first disconnect the washer from the power outlet.

Also, discharge the capacitor (by connecting a screwdriver to both capacitor terminals) to prevent getting zapped since the capacitor still has some charge in it.

Once you have done this, measure the capacitance through the capacitor terminals – is the reading you are getting similar to the nameplate values?

If it is not close to the nameplate values, it means that your capacitor could have fried.

The good new is that swapping out the capacitor yourself is not exactly rocket science.

Plus, it is an inexpensive part (see current price on Amazon)

GE washing machine not spinning or agitating – parting words

If you have a brand-new GE washing machine that is not spinning or agitating, it could be due to one of the following:

- Water might not be flowing into the appliance.

- You might be overloading/underloading your washer.

- The washer might not be properly balanced.

- You might not be closing the door fully.

- Something might be caught between the wash tub and the basket.

So, start by checking these parts.

ALSO READ

GE washing machine not spinning or draining [Fixed]

How to fix a GE top-load washer that won’t start but has power